Why Aluminum Foundries Are Important To the Growing Electric Vehicle Sector

Light weight aluminum factories play a critical duty in the electrical automobile market by supplying sturdy and light-weight elements. These materials add considerably to car performance and performance. The ingenious casting strategies utilized by foundries enable complex designs that boost both the rules of aerodynamics and thermal management. As sustainability comes to be a concern, the shift to recycled light weight aluminum and energy-efficient methods increases crucial inquiries regarding the future landscape of EV manufacturing and its ecological impact.

The Duty of Aluminum in Electric Lorry Style

As electrical automobile manufacturers look for to enhance efficiency and efficiency, light weight aluminum has become an important material in automobile design. Its light-weight nature adds considerably to the overall reduction of lorry mass, which is vital for optimizing battery performance and expanding range. Light weight aluminum is additionally extremely flexible, enabling elaborate layouts that improve aerodynamics and visual appeal. Its superb rust resistance warranties longevity, decreasing the demand for maintenance in time. Light weight aluminum's thermal conductivity help in effective heat administration systems, vital for electric drivetrains and battery durability. These features make light weight aluminum a favored selection for numerous parts, including chassis, body panels, and battery enclosures. As the industry develops, aluminum factories play an essential duty in providing high-quality materials tailored for advanced production procedures, thereby supporting the ongoing development in electric car innovation. This harmony between light weight aluminum and electrical automobile layout emphasizes the material's integral position in modern automotive design.

Benefits of Lightweight Products for EV Efficiency

Weight decrease is an essential consider enhancing electrical lorry (EV) efficiency. Lighter products, such as light weight aluminum, play a considerable function in this situation by improving effectiveness and prolonging the car's range. When an EV weighs less, it calls for less power to speed up and maintain rate, thus optimizing battery usage. This performance not just enhances efficiency however likewise adds to quicker billing times and minimized energy intake.

Furthermore, light-weight products improve taking care of and responsiveness, making the driving experience a lot more pleasurable. They additionally enable developers to produce even more aerodynamic shapes, additionally decreasing drag and boosting general performance. Furthermore, using light-weight materials can cause lower manufacturing costs and raised sustainability, as they typically need much less power to manufacture. Eventually, incorporating light-weight materials in EV layout is vital for attaining the performance objectives essential to compete in a significantly demanding automobile market.

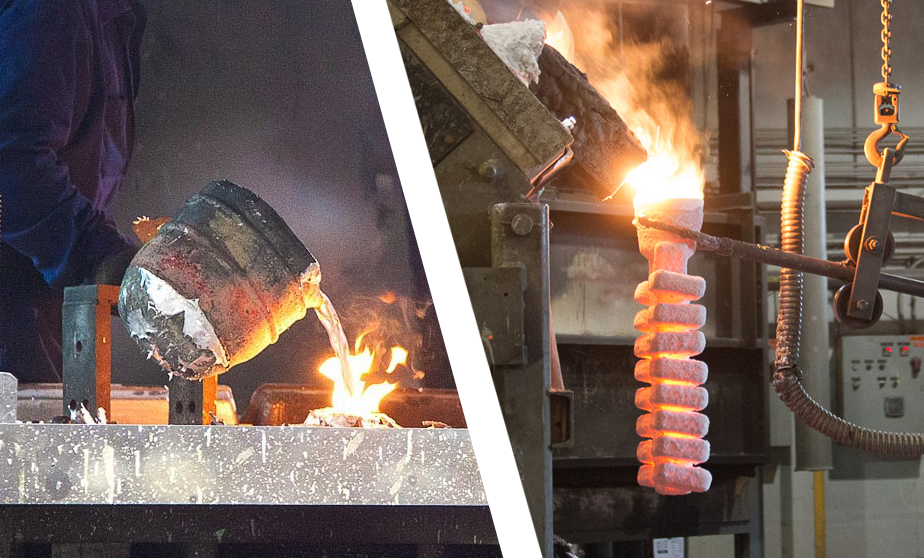

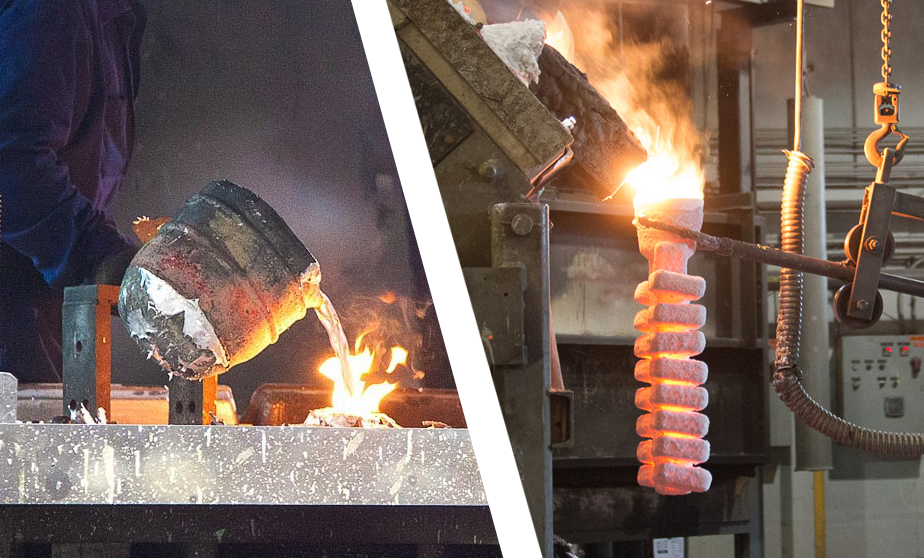

Technologies in Aluminum Casting Techniques

Current innovations in aluminum spreading strategies are revolutionizing the manufacturing procedure for electrical vehicle components. Advancements such as high-pressure die spreading and metal injection molding make it possible for the production of complicated geometries with improved toughness and lowered weight. These methods permit tighter resistances and boosted surface area coatings, which are crucial for EV performance and aesthetics.

These innovations not only support the requirement for lightweight elements yet additionally enhance the overall resilience and security of electric automobiles. As the market proceeds to evolve, these developments in aluminum casting are set to play an essential duty in fulfilling the demands of modern automotive style and manufacturing.

Sustainability and the Future of Aluminum Foundries

While the demand for electric cars rises, aluminum foundries face the pushing obstacle of taking on lasting techniques to minimize their ecological impact. The market is progressively inspected for read here its energy-intensive processes and carbon exhausts. To deal with these worries, factories are checking out innovative techniques such as utilizing recycled aluminum, which calls for significantly less energy than creating brand-new light weight aluminum from ore. In addition, the combination of sustainable power resources, like solar and wind, is coming to be extra common in aluminum manufacturing.

Investments in advanced technologies, such as electrical furnaces and energy-efficient spreading methods, additionally play an important role in boosting sustainability. Additionally, collaboration with auto suppliers can ensure that the whole supply chain prioritizes ecological responsibility. As the electric automobile market remains to grow, light weight aluminum foundries that welcome these sustainable methods will not just meet governing demands yet likewise place themselves as leaders in a significantly eco-conscious industry.

Situation Studies: Effective Applications of Light Weight Aluminum in EVs

As electrical car makers look for to improve efficiency and effectiveness, the calculated use light weight aluminum has actually emerged as an essential aspect in effective automobile style. Remarkable study show this trend. For circumstances, Tesla's Model S makes use of light weight aluminum extensively in its framework and body, considerably i loved this reducing weight while keeping structural honesty. This option not only enhances acceleration and variety however likewise improves safety features.

Ford's F-150 Lightning integrates aluminum to achieve a reduced total weight, permitting for boosted payload capacity and better power effectiveness (Precision aluminum casting). The vehicle's light weight aluminum body panels and structure contribute to a robust yet light-weight framework, assisting in improved efficiency

In addition, Audi's e-tron showcases aluminum's flexibility, utilizing it in both the automobile's body and battery housing, enhancing thermal monitoring and longevity. These instances demonstrate just how light weight aluminum's distinct residential properties are being leveraged across the electric lorry market, setting standards for advancement and sustainability.

Frequently Asked Inquiries

What Sorts Of Aluminum Alloys Are Frequently Used in EV Production?

Typically made use of light weight aluminum alloys in electric lorry production consist of 6061, 7005, and 2024. These alloys provide a mix of strength, light-weight homes, and deterioration resistance, making them suitable for various elements within electrical cars.

Just How Do Aluminum Foundries Effect Citizen Economies?

Aluminum shops greatly improve neighborhood economic climates by developing jobs, promoting relevant industries, and drawing in financial investments - aluminum casting. Their procedures lead to enhanced need for solutions and materials, fostering growth and security within the bordering areas

What Are the Safety Considerations of Utilizing Light Weight Aluminum in EVS?

Safety and security considerations of using aluminum in electrical lorries include its flammability, structural integrity under effect, and capacity for rust. Correct alloy option and therapy processes are vital to guarantee performance and security during automobile procedure.

How Does Aluminum Recycling Impact the Sector?

Aluminum recycling substantially benefits the industry by minimizing manufacturing costs, reducing ecological influence, and preserving energy. This sustainable method boosts source efficiency, supporting the growth of electric automobiles and advertising a round economy within the automobile market.

What Are the Labor Demands for Light Weight Aluminum Foundries in EV Manufacturing?

Labor needs for light weight aluminum foundries in electric vehicle production include competent professionals for spreading, designers for layout and optimization, and safety and security employees. In addition, training in reusing procedures boosts performance and sustainability in the manufacturing chain.

Aluminum foundries play a critical duty in the electrical vehicle market by offering resilient and lightweight components. As electrical lorry suppliers look for to improve performance and effectiveness, this page light weight aluminum has actually arised as a vital material in automobile style. As the market develops, aluminum foundries play a crucial duty in supplying top quality materials tailored for sophisticated manufacturing procedures, consequently supporting the ongoing technology in electrical car technology - Precision aluminum casting. To resolve these worries, factories are exploring cutting-edge techniques such as making use of recycled light weight aluminum, which requires substantially less power than creating new light weight aluminum from ore. As electric lorry makers seek to boost performance and performance, the tactical use of light weight aluminum has actually emerged as a key aspect in successful automobile design